Using High Quality Adhesive Solutions in Your Business

2023/2/1 Celadon Tech - RDBoost your business success by incorporating high quality adhesive solutions into your operations. Find out more in this post!

For businesses in any industry, adhesive solutions provide a reliable way to meet production requirements and increase efficiency. This article will cover the range of applications for adhesive solutions and how they can benefit any operation.

Every business application requires different levels of adhesion and different products to ensure reliable results. Celadon is specialize in PSA single and double-side tape solutions. When selecting an adhesive solution, it’s important to consider the specific application you need and the surface materials that need to be bonded. Selecting the correct product is key to delivering your desired outcomes. Consider talking with a specialist in order to determine the right product for your needs.

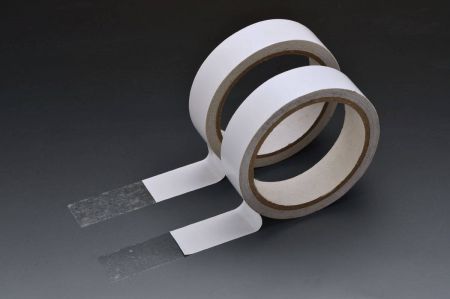

Pressure Sensitive Adhesive (PSA) tapes are a type of adhesive solution that have become increasingly popular in various industries. These tapes are characterized by their ability to adhere to surfaces without the need for additional heat or pressure, making them an ideal solution for a range of applications. In this article, we will explore the benefits of PSA tapes and some of the key factors to consider when choosing the right tape for your needs.

One of the primary benefits of PSA tapes is their convenience. Unlike other adhesives that require heat or pressure to activate, PSA tapes simply need to be applied to a surface to create a bond. This makes them easy to use and reduces the time and cost associated with other joining methods.

Another benefit of PSA tapes is their versatility. They come in a range of materials and thicknesses, making them suitable for a variety of applications. For example, foam PSA tapes are often used for insulation and cushioning, while plastic PSA tapes are ideal for packaging and labeling.

In addition, PSA tapes offer a clean, professional appearance, making them an ideal solution for a range of products, including electronics, medical devices, and consumer goods. PSA tapes are also durable, providing a strong bond that can withstand environmental factors such as heat, humidity, and UV radiation.

When choosing a PSA tape, it's important to consider a number of key factors. For example, the temperature and humidity range of the environment in which the tape will be used can impact its performance, so it's important to choose a tape that is suitable for these conditions. Additionally, the type of surface that the tape will be applied to can impact its performance, so it's important to choose a tape that is compatible with the material.

Another factor to consider is the type of release liner used on the tape. Release liners are the backing material on which the adhesive is applied. They play a key role in the performance of the tape and can impact its ability to adhere to surfaces and release from the liner.

In conclusion, PSA tapes are a convenient and versatile adhesive solution that offer a range of benefits over other joining methods. When choosing a PSA tape, it's important to consider a range of factors, including the environment in which the tape will be used, the type of surface it will be applied to, and the type of release liner used. Whether you are looking for a strong, reliable bond for your product or a convenient solution for your application, PSA tapes are an ideal choice.

- Related Products

Tissue Double Coated Adhesive Tape

DS1-ABW49100

Description During the lifetime of vehicle, boat or yacht static and dynamic stresses act upon the constructive bond between the object and the subject part. Celadon® Double Coated Tape creates a powerful bond even between materials with different surface characteristics, such as low surface energy, EVA, EPDM form, plastic parts connection. Celadon Tissue Double Coated Adhesive Tape is 0.15mm double coated with solvent base poly-acrylic pressure sensitive adhesive and backing with 110gsm silicon coated release paper liner. Application Techniques The bond strength of Celadon depends on the area of adhesive to surface contact developed during application and substrate type and surface conditions. For maximum bond strength, the surfaces should be thoroughly cleaned with a 50:50 mixture of isopropyl alcohol and water. Ideal tape application is accomplished when the temperature is between 21°C-38°C (70°F-100°F) and the bond is allowed to dwell 72 hours. Initial tape application to surfaces at temperatures below 10°C (50°F) is not recommended. Moderate heat lamination (65°C at 72.5 psi for 1-5 minutes) is recommended on rough surfaces.STORAGE and SHELF LIFE The shelf life of Celadon Adhesive Transfer Tape ATR2165 is 6 months from the date of manufacture when stored in the original packaging materials and stored at 21°C (70°F) and 50% relative humidity.

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More