FAQ

Q & A

Step into the vibrant world of vinyl for sandblasting and unleash your artistic potential like never before. With its versatility and precision, vinyl has revolutionized the art of sandblasting, allowing artists and craftsmen to create intricate designs and stunning visual effects with ease.

Whether you're a professional artist or a DIY enthusiast, vinyl for sandblasting opens up a whole new realm of possibilities. From customizing glassware and mirrors to adding unique patterns and textures to metal, vinyl provides the perfect canvas for your creativity to flourish.

With its adhesive backing and durability, vinyl stencils offer precise and clean lines, ensuring your designs are flawlessly transferred onto the surface. From simple shapes to intricate patterns, the possibilities are endless. Plus, the pressure from the sandblasting process ensures the design is etched deep into the material, creating a lasting impression that will withstand the test of time.

So, why limit your artistic vision? Embrace the vibrant world of vinyl for sandblasting and unlock limitless possibilities to elevate your craft to new heights. Let your imagination run wild and watch as your creations come to life with every delicate blast of sand.

Keywords: vinyl for sandblasting, artistic potential, versatile, precision, stencil, creative, sandblasting process, lasting impression.

Vinyl sandblasting is a unique and captivating art form that has gained immense popularity in recent years. At its core, the process involves using vinyl stencils to create intricate designs and patterns on various surfaces through the power of sand-blasting. The technique is simple yet effective, allowing artists and craftsmen to unleash their creativity in ways that were previously unimaginable.

The process of vinyl sandblasting begins with the creation of a vinyl stencil. These stencils are precision-cut using specialized cutting machines or even by hand, depending on the complexity of the design. The vinyl material is carefully selected for its durability and adhesive properties, ensuring a secure bond with the surface being etched. Once the stencil is in place, the sandblasting process commences, with a high-powered stream of sand or other abrasive media being directed at the exposed areas of the surface.

The force of the sandblasting process etches the design into the material, creating a permanent and visually striking impression. The depth and texture of the etching can be adjusted by varying the pressure, duration, and angle of the sandblasting, allowing artists to achieve a wide range of effects, from delicate and intricate patterns to bold and textured designs. The versatility of this technique enables it to be applied to a diverse range of materials, including glass, metal, stone, and even wood, making it a truly versatile and captivating art form.

One of the primary advantages of using vinyl for sandblasting is its exceptional versatility. Vinyl stencils offer a level of precision and control that is unmatched by other materials, allowing artists to create intricate and detailed designs with ease. The adhesive backing of the vinyl ensures a secure and seamless bond with the surface being etched, preventing any unwanted bleeding or blurring of the design during the sandblasting process.

Another significant benefit of vinyl for sandblasting is its durability. The material is designed to withstand the intense pressure and abrasion of the sandblasting process, ensuring that the stencil maintains its integrity and delivers consistent, high-quality results. This durability also translates to the longevity of the final product, as the etched designs are deeply embedded into the surface and are resistant to wear and tear over time.

Furthermore, vinyl for sandblasting offers a wide range of color options, enabling artists to incorporate vibrant hues and striking contrasts into their designs. This versatility allows for the creation of truly unique and eye-catching pieces that stand out from the crowd. Whether you're looking to create custom glassware, personalized metal signs, or intricate patterns on stone, vinyl stencils provide the perfect canvas for your artistic vision.

When it comes to vinyl for sandblasting, there are several different types to choose from, each with its own unique characteristics and applications. One of the most common types is adhesive-backed vinyl, which features a strong adhesive layer that allows the stencil to adhere securely to the surface being etched. This type of vinyl is ideal for a wide range of materials, including glass, metal, and stone.

Another popular option is removable vinyl, which is designed to be easily peeled off the surface after the sandblasting process is complete. This type of vinyl is particularly useful for creating temporary or reusable stencils, allowing artists to experiment with different designs and patterns without the need to create a new stencil for each project.

For more intricate and detailed designs, artists may opt for pre-cut vinyl stencils, which are precision-cut using specialized cutting machines. These stencils often feature complex patterns and shapes, making them ideal for creating detailed and visually striking designs. Alternatively, some artists prefer to create their own custom vinyl stencils using cutting machines or even by hand, allowing for a greater level of creative control and personalization.

Engaging in the art of vinyl sandblasting requires a specific set of tools and equipment to ensure the process is carried out efficiently and effectively. At the core of this setup is the sandblasting cabinet, a specialized enclosure that houses the sandblasting equipment and protects the user from the abrasive media used in the process.

Within the sandblasting cabinet, the key components include the air compressor, which provides the necessary air pressure to propel the sand or other abrasive media, and the sandblasting gun, which directs the stream of abrasive material onto the surface being etched. The choice of abrasive media, such as fine-grained sand, glass beads, or aluminum oxide, can have a significant impact on the final result, as different materials can produce varying levels of texture and depth in the etched design.

In addition to the core sandblasting equipment, artists and craftsmen will also need a range of tools to prepare the surfaces and apply the vinyl stencils. This may include cutting mats, utility knives, and precision cutting tools for creating the stencils, as well as cleaning supplies and masking materials to ensure a clean and seamless application of the vinyl. By assembling the right tools and equipment, artists can unlock the full potential of vinyl sandblasting and bring their creative visions to life with unparalleled precision and control.

Embarking on a vinyl sandblasting project requires a methodical approach to ensure the best possible results. Let's dive into the step-by-step process that will guide you through the journey of unleashing your artistic potential.

- Design and Preparation: Begin by creating or selecting the design you wish to etch onto your chosen surface. This can be a simple geometric pattern, a complex illustration, or even a personalized monogram. Once you have the design, use a cutting machine or manual cutting tools to precisely cut the vinyl stencil.

- Surface Preparation: Thoroughly clean and degrease the surface you'll be working on, whether it's glass, metal, or any other material. This step is crucial to ensure the vinyl stencil adheres securely and the sandblasting process delivers a flawless result

- Stencil Application: Carefully align and apply the vinyl stencil to the prepared surface, smoothing out any air bubbles or wrinkles to create a seamless bond. Make sure the edges of the stencil are firmly adhered to prevent any unwanted bleed-through during the sandblasting process.

The world of vinyl sandblasting is a vast and exciting canvas for artistic expression, offering endless possibilities for creative exploration. From the simplest of geometric shapes to intricate, detailed designs, the versatility of this medium allows artists to push the boundaries of their creativity.

One captivating avenue to explore is the incorporation of text and typography into your vinyl sandblasting designs. Whether it's a bold, eye-catching statement, a delicate script, or a playful monogram, the precise etching of letters and words can create a stunning visual impact. Imagine personalizing glassware, mirrors, or even metal signs with your own unique typographic designs, adding a touch of personalization and flair to your creations.

Another compelling direction for vinyl sandblasting is the exploration of nature-inspired motifs. From delicate floral patterns to intricate wildlife silhouettes, the natural world offers a wealth of inspiration for captivating designs. By translating these organic forms into vinyl stencils, artists can breathe life into their creations, transforming ordinary surfaces into enchanting works of art.

Embarking on a vinyl sandblasting project can be an exciting and rewarding journey, but it's important to keep a few key tips in mind to ensure your success. One of the most crucial factors is the quality and preparation of the vinyl stencil. Take the time to carefully design and cut your stencil, ensuring clean, precise edges and a secure adhesion to the surface. This attention to detail will pay dividends in the final result, as it will prevent any unwanted bleeding or blurring of the design.

Another essential tip is to meticulously prepare the surface before applying the vinyl stencil. Thorough cleaning and degreasing are essential to creating a smooth, uniform surface that will allow the stencil to adhere properly. This step not only ensures the longevity of your design but also helps to prevent any imperfections or inconsistencies in the final etched result.

Finally, mastering the art of sandblasting itself is crucial to achieving the desired outcome. Experiment with different abrasive media, pressure settings, and blasting angles to find the perfect balance that brings your vinyl design to life. Pay close attention to the depth and texture of the etching, adjusting your technique as needed to capture the essence of your artistic vision.

While vinyl sandblasting has emerged as a highly versatile and captivating art form, it is not the only technique available for creating intricate designs and patterns on various surfaces. It's important to understand the unique advantages and limitations of vinyl sandblasting in comparison to other popular methods, allowing you to make an informed decision on the best approach for your creative projects.

One alternative to vinyl sandblasting is the use of traditional stencils, which can be made from a variety of materials, such as paper, plastic, or metal. These stencils offer a more budget-friendly option, but they may lack the precision and durability of vinyl. Additionally, the sandblasting process can be more challenging with traditional stencils, as the abrasive media can potentially seep under the edges, resulting in less defined and consistent designs.

Another technique to consider is laser etching, which uses a high-powered laser to precisely etch designs into various materials. While laser etching can produce remarkably detailed and intricate designs, it is often a more expensive and specialized process, requiring specialized equipment and expertise. In contrast, vinyl sandblasting offers a more accessible and versatile approach, allowing artists and craftsmen to create stunning results with a relatively simple setup and a lower barrier to entry.

As you've discovered throughout this exploration, the world of vinyl sandblasting is a vibrant and captivating realm that offers endless possibilities for artistic expression. By harnessing the power of this versatile medium, you can unlock new levels of creativity and elevate your craft to new heights.

Whether you're a seasoned artist, a budding craftsman, or simply someone with a passion for unique and personalized creations, vinyl sandblasting provides the perfect canvas for your imagination to flourish. From customizing glassware and mirrors to adding one-of-a-kind patterns and textures to metal, stone, and wood, the possibilities are truly limitless.

As you delve deeper into the art of vinyl sandblasting, embrace the journey of experimentation and discovery. Explore different design ideas, experiment with various vinyl types and abrasive media, and constantly challenge yourself to push the boundaries of what's possible. With each successful project, you'll not only hone your skills but also uncover new avenues for creative expression, ultimately transforming ordinary surfaces into extraordinary works of art.

So, what are you waiting for? Unleash your artistic potential and dive into the vibrant world of vinyl sandblasting. Let your imagination soar, and watch as your creations come to life, leaving a lasting impression that will captivate and inspire all who behold them.

With advancements in printing technology, digitally printed vinyl has become more accessible and cost-effective than ever before. This versatile medium not only enhances the visual appeal of promotional materials but also offers durability and weather resistance, making it ideal for both indoor and outdoor applications.

Whether you're a business owner looking to create eye-catching marketing materials or a designer aiming to bring your visions to life, understanding the ins and outs of digital printed vinyl is essential. This comprehensive guide will take you through everything you need to know, from the different types of vinyl to the best practices for designing and applying graphics.

Join us as we explore the exciting world of digital printed vinyl and discover how this innovative printing method can elevate your graphics and design projects. Get ready to unleash your creativity and make a lasting impact with stunning digital printed vinyl graphics.

Digital printed vinyl has become a game-changer in the world of graphics and design, offering a multitude of benefits that make it a preferred choice for businesses and creatives alike. One of the primary advantages of this innovative printing method is the exceptional quality of the final output. Digital printing technology has advanced to a point where it can produce stunningly vibrant, high-resolution graphics that rival traditional printing techniques. The colors are rich and true-to-life, ensuring that your designs pop off the surface and capture the attention of your audience.

Another significant benefit of digital printed vinyl is its versatility. This medium can be used for a wide range of applications, from custom signage and vehicle wraps to trade show displays and interior decor. The ability to print on large-format vinyl allows for the creation of eye-catching, large-scale graphics that make a lasting impression. Additionally, digital printed vinyl is highly durable and weather-resistant, making it an ideal choice for outdoor applications that need to withstand the elements.

Cost-effectiveness is another major advantage of digital printed vinyl. Traditional printing methods often require high setup costs and minimum order quantities, making them less accessible for small businesses and individual designers. In contrast, digital printing technology has become more affordable and efficient, allowing for smaller print runs and personalized projects without breaking the bank. This accessibility has opened up new opportunities for businesses and creatives to explore the endless possibilities of custom graphics and branding.

When it comes to digital printed vinyl, there are several distinct types to choose from, each with its own unique characteristics and applications. One of the most common types is calendered vinyl, which is a cost-effective and durable option for indoor and short-term outdoor use. Calendered vinyl is known for its smooth surface and excellent printability, making it a popular choice for signage, decals, and vehicle graphics.

Another type of digital printed vinyl is cast vinyl, which is known for its superior conformability and long-term durability. Cast vinyl is often used for applications that require the material to conform to complex surfaces, such as vehicle wraps and deep-channel lettering. This type of vinyl is also highly resistant to fading and weathering, making it an ideal choice for long-term outdoor use.

Specialty vinyl options, such as reflective vinyl and metallic vinyl, are also available for digital printing. Reflective vinyl is designed to enhance visibility and safety, making it a popular choice for road signs, safety markings, and emergency vehicle graphics. Metallic vinyl, on the other hand, adds a touch of elegance and sophistication to your designs, making it a popular choice for high-end branding and promotional materials.

Selecting the right type of digital printed vinyl for your project is crucial to ensuring the best possible outcome. When making your decision, consider factors such as the intended use, the surface on which the vinyl will be applied, and the expected lifespan of the graphics.

For indoor applications or short-term outdoor use, calendered vinyl may be the most cost-effective and practical choice. If your project requires the vinyl to conform to complex surfaces or withstand long-term outdoor exposure, cast vinyl may be the better option. Specialty vinyl types, such as reflective or metallic, can be utilized to add unique visual elements and enhance the overall impact of your design.

It's also important to consider the specific properties of the vinyl, such as its thickness, adhesive strength, and removability. Thicker vinyls may be more durable but may also be more challenging to apply, while removable vinyls can be a valuable option for temporary installations or changing graphics over time. Consulting with a professional digital printing company can help you navigate the various vinyl options and make an informed decision that aligns with your project's needs.

The process of digital printing on vinyl involves several key steps that ensure high-quality, long-lasting graphics. The first step is the design and file preparation stage, where your artwork or graphics are created and optimized for the digital printing process. This may involve adjusting the file resolution, color profiles, and other design elements to ensure that the final output meets your desired specifications.

Once the design is ready, the digital printing process begins. Digital printers use advanced inkjet technology to apply vibrant, high-resolution inks directly onto the vinyl substrate. The inks used in digital printing are specifically formulated for compatibility with vinyl, ensuring excellent adhesion and durability. The printing process is highly precise, with the ability to produce fine details and intricate designs with exceptional clarity.

After the printing is complete, the vinyl may undergo additional processing, such as lamination or clear-coating, to enhance its durability and protection against environmental factors. Lamination, in particular, can help to extend the lifespan of the graphics by providing an additional layer of protection against scratches, UV exposure, and other potential hazards. The final step in the process is the application of the printed vinyl, which requires careful attention to surface preparation, alignment, and smoothing to ensure a professional, seamless finish.

The versatility of digital printed vinyl makes it a popular choice for a wide range of graphics and design applications. One of the most common uses is custom signage, where vinyl graphics can be printed and applied to a variety of surfaces, from indoor office walls to outdoor building facades. This allows businesses and organizations to create eye-catching, personalized signage that reinforces their brand identity and conveys important information to their target audience.

Another popular application of digital printed vinyl is vehicle wraps. By covering the entire surface of a vehicle with a custom-printed vinyl wrap, businesses can transform their fleet into rolling billboards, effectively promoting their brand and services. Vehicle wraps are not only visually striking but also highly durable, protecting the underlying paint and withstanding the elements for an extended period.

Digital printed vinyl also shines in the realm of trade show and event displays. From large-format banners and backdrops to custom-shaped displays and three-dimensional structures, this medium allows designers to create immersive, attention-grabbing environments that leave a lasting impression on attendees. The ability to print high-quality graphics on a flexible, lightweight material makes digital printed vinyl an ideal choice for these dynamic, high-visibility settings.

When it comes to digital printed vinyl, the quality of the final product is heavily dependent on the expertise and capabilities of the printing company you choose. It's essential to do your research and select a provider that has a proven track record of delivering exceptional results and customer service.

Look for a digital printing company that uses the latest printing technology and high-quality materials. They should have a wide range of vinyl options, including different types, thicknesses, and finishes, to ensure that you can find the perfect solution for your project. Additionally, the company should have a team of experienced designers and technicians who can guide you through the process, from file preparation to installation.

Reliability and turnaround time are also crucial factors to consider when selecting a digital printing company. Look for a provider that can deliver your project on time and within your budget, without compromising on quality. Reach out to the company and gauge their responsiveness, communication, and willingness to address your specific needs. By choosing a reliable digital printing partner, you can be confident that your graphics and design projects will be brought to life with the utmost care and professionalism.

Proper maintenance and care are essential for ensuring the longevity and optimal performance of your digital printed vinyl graphics. Whether you've installed custom signage, vehicle wraps, or any other vinyl-based application, following a few simple guidelines can help preserve the vibrant colors and protect the integrity of the material.

One of the most important aspects of vinyl maintenance is regular cleaning. Depending on the location and exposure of your graphics, you may need to clean them weekly or monthly. Use a mild, non-abrasive cleaning solution and a soft cloth or sponge to gently wipe away any dirt, dust, or debris. Avoid using harsh chemicals or high-pressure washers, as these can damage the vinyl's surface and adhesive.

For outdoor applications, such as vehicle wraps or building signage, it's crucial to monitor the vinyl for any signs of wear or damage, such as peeling, cracking, or fading. If you notice any issues, it's best to address them promptly by consulting with a professional vinyl graphics specialist. They can assess the problem and recommend the appropriate course of action, whether it's a simple repair or a full replacement.

By following these maintenance best practices, you can ensure that your digital printed vinyl graphics maintain their vibrant appearance and continue to deliver the desired impact for years to come. Investing in proper care and upkeep will not only extend the lifespan of your vinyl but also preserve the investment you've made in your branding, marketing, and design efforts.

Digital printed vinyl has undoubtedly revolutionized the world of graphics and design, offering a versatile, high-quality, and cost-effective solution for businesses and creatives alike. From custom signage and vehicle wraps to trade show displays and interior decor, this innovative printing medium has transformed the way we approach visual communication and branding.

By understanding the benefits, types, and applications of digital printed vinyl, you can unlock a world of creative possibilities and elevate your graphics to new heights. Whether you're a business owner looking to make a lasting impression or a designer seeking to bring your visions to life, embracing the power of digital printed vinyl can be a game-changer for your projects.

As you embark on your journey with digital printed vinyl, remember to choose the right type of material for your specific needs, work with a reliable printing partner, and maintain your graphics with care. By doing so, you'll ensure that your investment in custom graphics continues to deliver results and leave a lasting impact on your audience.

The revolution of digital printed vinyl is here, and the opportunities it presents are endless. Embrace this innovative medium, unleash your creativity, and let your graphics take center stage. The future of graphics and design is digital printed vinyl, and the time to be a part of this exciting transformation is now.

Adhesive Strength Test

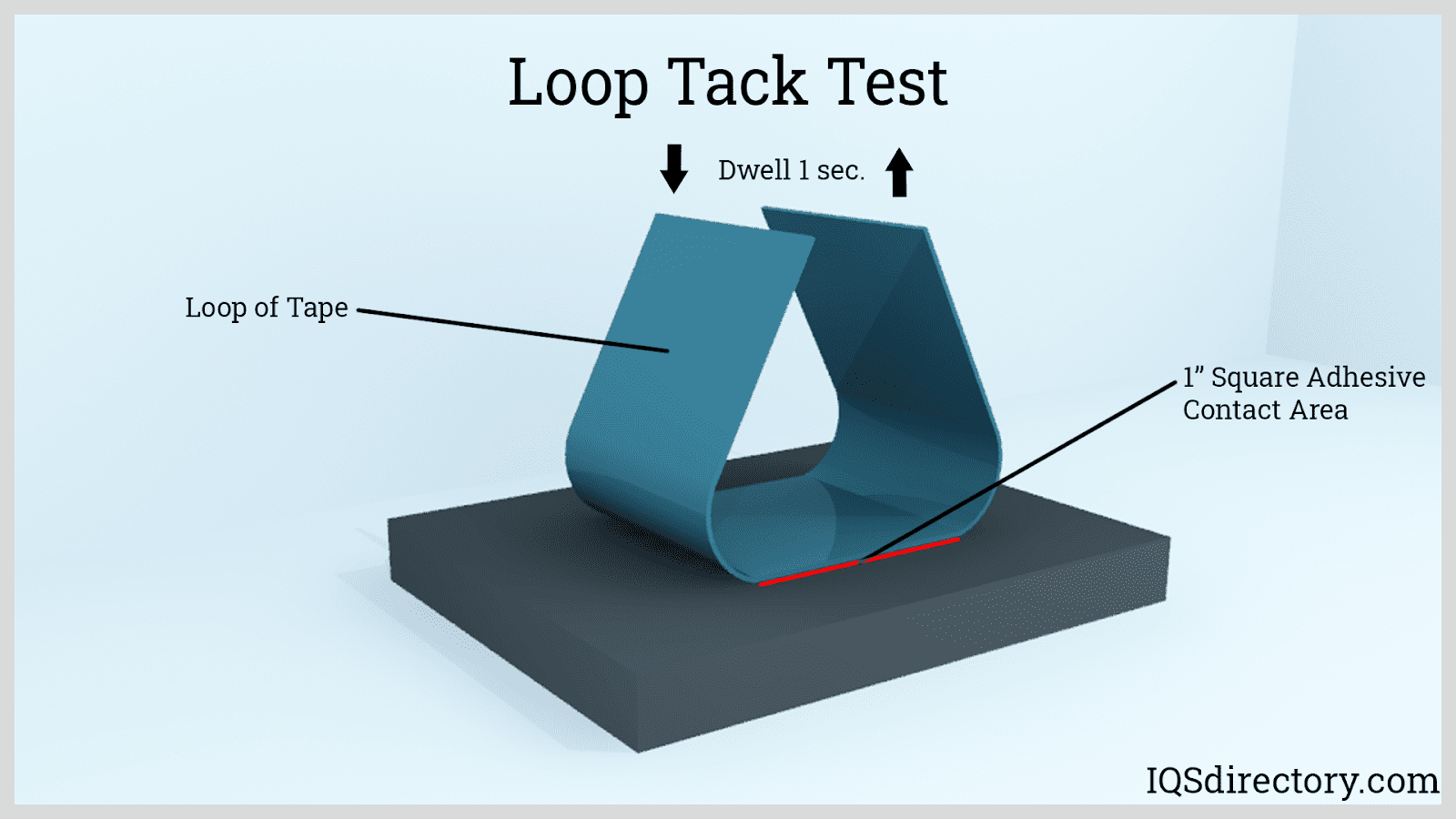

Loop Tack Test

Several methods are used to measure the tackiness of pressure sensitive adhesives attached to films, labels, stickers, and tapes. These include loop tests and 90º and 180º peel tests. In the loop test, a loop of adhesive tape attached to the probe of the testing machine makes contact with a horizontal surface and is pulled away after a short time. This measures the maximum force needed to peel off the tape from the substrate. In the 90º peel test, the adhesive tape is attached to a horizontal plate with the other end sticking up perpendicularly, forming an “L” shape. In the 180º peel test, the adhesive tape is placed vertically between the peel test grips with the free end of the tape gripped by the top forming a tight “U” shape. The 90º and 180º peel adhesion tests measure the constant force required to peel off the tape rather than the maximum force. The 90º peel adhesion test normally gives a lower value than the 180º peel adhesion test.

Celadon Technology Company Ltd. specializes in the production of premium vinyl graphic products and adhesive systems used in commercial and industrial applications. We implement stringent quality control procedures to ensure our products are of the best quality. We also have a dedicated research and development team to provide custom solutions to our client’s needs. Visit our website to learn more about us.

Read MoreCast PVC

The term “cast” refers to the manufacturing process of cast PVC. Cast PVC is produced by first dissolving the PVC, plasticizer, and colorant using a solvent. Consequently, a thin film of the liquid mixture will then be poured onto a casting sheet. After that, it will be dried and cured in a series of ovens at a high temperature, producing a flexible film with a smooth finish. The casting sheet determines the texture of the surface of the film.

Because the temperature used during drying and curing processes is higher than that used in applications of the final product, cast PVC can withstand distortion, degeneration, warping, or degradation due to heat. It also has high dimensional stability since no pressure is applied during the production process. In addition, cast PVC is thinner, softer, and more flexible than calendered PVC, making them suitable for use in complex applications such as vehicle wrapping. Films produced by casting can last up to 12 years. However, casting is not suitable for large-scale production because of its high production cost; it also cannot produce wide-width films.

Calendered PVC

Matt Opaque Color Vinyl for Car Wrapping

Calendered PVC is created by melting the PVC, plasticizer, and colorant altogether. The molten materials then are pressed by calendering rollers to achieve the desired width, thickness, and surface finish of the film. Calendered PVC is thinner and less resilient than cast PVC, but calendered PVC is suitable for many applications. It is usually used for short to medium-term applications that do not require conforming around complex surfaces such as point-of-purchase displays, window graphics, and partial wraps. The production cost of calendered PVC is lower than that of cast PVC because solvent and molds are not needed in manufacturing. Its service life usually lasts from two to seven years depending on the type of plasticizer used.

Read MoreMonomers are molecules that contain only carbon and hydrogen atoms. Polymers are made up of many monomers linked together. Calendering is a process where polymer films are stretched and heated to make them thinner and stronger. The most common types of calendered films are monomeric and polymeric. Monomeric films are usually used for packaging applications because they are strong and flexible. Polymeric films are often used for printing on paper products.

The Calendering Process

In order to create a calendered film, we first need to melt PVC resin, plasticizers and colorants together. Once melted, we pass the PVC through a series of rollers which flatten out the material and smooth out any imperfections. After passing through the rollers, the PVC is winded onto a spool.

About Plasticizer

The most common type of plasticizer used in vinyl flooring is phthalate esters. Phthalates are chemicals that soften plastics so they can be molded easily. Vinyl flooring contains a lot of phthalates because they make the vinyl flexible enough to mold. But these chemicals aren’t good for people. They can cause health issues like reproductive problems, hormone disruption, and cancer. That’s why we use only high quality REACH certificated plasticizers that don’t contain any harmful chemicals.

What do Monomeric and Polymeric mean?

Mono- and polymers are both chemical compounds that consist of long chains of atoms. The difference between mono- and polymers is how these chains are connected together. In monomers, each chain is attached to only one other chain. This makes monomers very small molecules. In polymers, on the other hand, there are multiple connections between chains. These connections make polymers much larger than monomers.

Polymeric Films

Polymeric films are made of long-chain plasticizers. Longer chain molecules bond together much better than short ones, so polymers are much stronger than monomers. They also have a higher glass transition temperature, which makes them more resistant to heat and cold. Polymer films are typically thicker than monomeric films, ranging from 100–400 microns. This allows them to withstand harsh environments like snow, rain, wind, and salt spray. Polymers also have a longer-lasting outdoor durability than monomers.

Polymeric PVC film has a better outdoor durability

Monomeric Films

Monomeric films are made of short-chain plasticizers. These short chains do not bind into the film very well. Overall, the short-chain plasticizers tend to migrate out of the film, making it brittle. In addition, monomeric film varies in thickness. It can be between 80 400 micron thick and has a tendency to shrink. especially the softer and flexible film. Therefore, these films are best for indoor flat applications and have a 3 – 5 year outdoor durability. Lastly, monomeric films have short-term outdoor durability that varies by manufacturer, making them more economical.

Monomeric PVC film is suitable for indoor or short-term outdoor application

Polymeric Film | Monomeric Films |

|

|

Read More

Parts of the Bond

The bonding layer made by an adhesive tape, shown macroscopically in the image below, presents a cross-section of a bond. The layer consists of an adhesion zone, cohesion zone, and a transition layer.

The adhesion zone is the interfacial layer between the adhesive and the substrate. The cohesion zone is the pure adhesive layer that holds the adhesive and the backing material, or another substrate if the adhesive is unsupported. The transition layer is intermediate between the adhesion and cohesion zones.

Mechanism of Action

The mechanism of adhesive tape bonding occurs as follows. These steps can be accomplished instantly after the activation of the pressure-sensitive adhesive.

- The pressure-sensitive adhesive on the tape is made to contact with the substrate by minimal pressure.

- Adhesive increases its surface area and penetrates through the surface of the substrate.

- Adhesive sets on the substrate, producing a strong bond.

The three elements of a pressure-sensitive adhesive tape to achieve a successful bond are adhesion, cohesion, and tackiness.

- Adhesion: Adhesion refers to the ability of an adhesive to stick on the surface of the substrate through adhesive forces. Adhesive forces refer to the attraction of two different materials. When the substrate and the adhesive molecules come in close proximity, adhesion forces occur at the microscopic level through intermolecular forces (e.g., van der Waals forces, dispersion forces) between them.

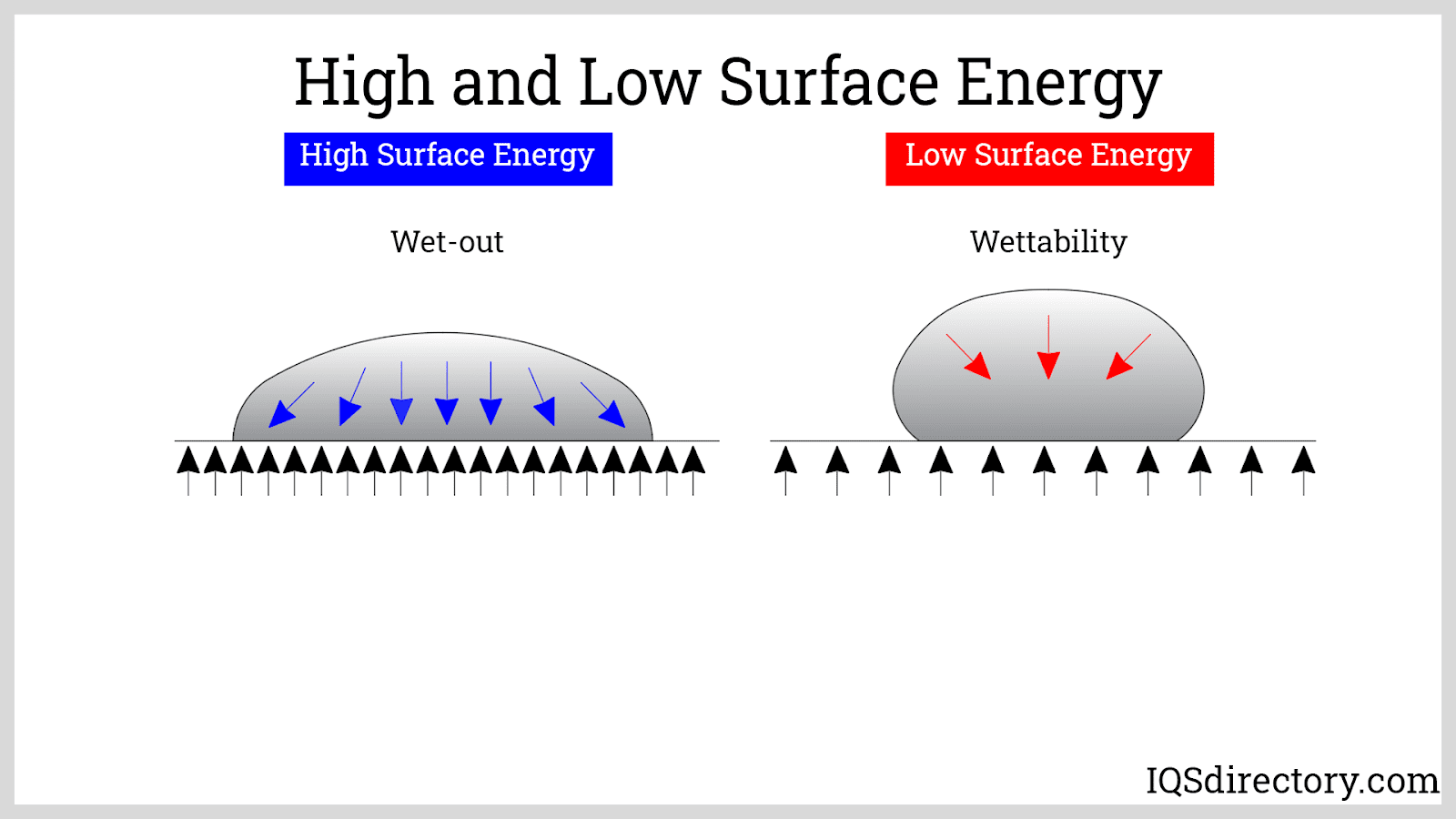

Surface energy is one of the properties which determines the wettability of the substrate when it comes in contact with the adhesive. Wettability is important to penetrate the surface of the substrate, thus making a continuous bond.

Surface energy is defined as the sum of the intermolecular forces, and the attraction and repulsion energies which a liquid exerts on the surface of a solid. If the substrate has high surface energy, the adhesive will easily flow on its surface and more surface area will be covered. Some of the high-energy substrates include polycarbonate, polyvinyl chloride, and zinc. On the other hand, if the substrate has low surface energy, the adhesive will build up as “small beads” and only a small area will be covered. Low surface energy substrates include Teflon, rubber, powder coatings, etc.

Surface contaminants prevent the fusion of the adhesive into the substrate. Therefore, it is important to keep the surface free from grease, dirt, and moisture before application of the adhesive tape.

- Cohesion: Cohesion is the inner strength of the adhesive. It refers to the bonding of the adhesive within itself. Cohesion holds the adhesive layer intact and prevents it from splitting.

Cohesive forces attract the neighboring molecules of a liquid by pulling it inward. Molecules at the surface of the liquid have greater attractive forces that bind them together. This phenomenon is responsible for the property of a liquid called surface tension. Surface tension is the ability of the adhesive to resist deformation on the surface of a solid, thus reducing its surface area. In the case of adhesive tapes, the molecules of the adhesive must be strong cohesive forces to hold and maintain the bond over time.

Silicone is an example of a liquid with high surface tension. If silicone is present as a coating on the surface of the substrate, it will be difficult to be wetted by the adhesive. If used as an adhesive, on the other hand, it will produce a durable bond.

Adhesion and cohesion must be considered when formulating or choosing the right adhesives. An ideal bond consists of a combination of a high surface energy substrate and a low surface tension adhesive. To achieve good wetting of the substrate, adhesive forces must be greater compared to cohesive forces and the contact angle must be less than 90°.

- Tackiness: Tackiness refers to the characteristic of a pressure-sensitive tape by which the adhesive sticks to the surface of the substrate under minimal pressure. All pressure-sensitive adhesives are activated by an initial finger pressure applied to the tape, usually from 14.5 to 29 psi. The required pressure and contact time for the adhesive tape to stick varies according to the type of adhesive and substrate material. Less pressure and contact time are required to stick for adhesive tapes with higher tack.

The phenomenon described is attributed to the viscoelasticity of the adhesive at room temperature. Viscoelastic objects are materials that possess both viscous and elastic characteristics. When gentle pressure is applied to the tape, it decreases its viscosity thus encouraging flow on the substrate at the microscopic level. Due to its elastic property, the original viscosity is regained with stronger intermolecular force with the substrate.

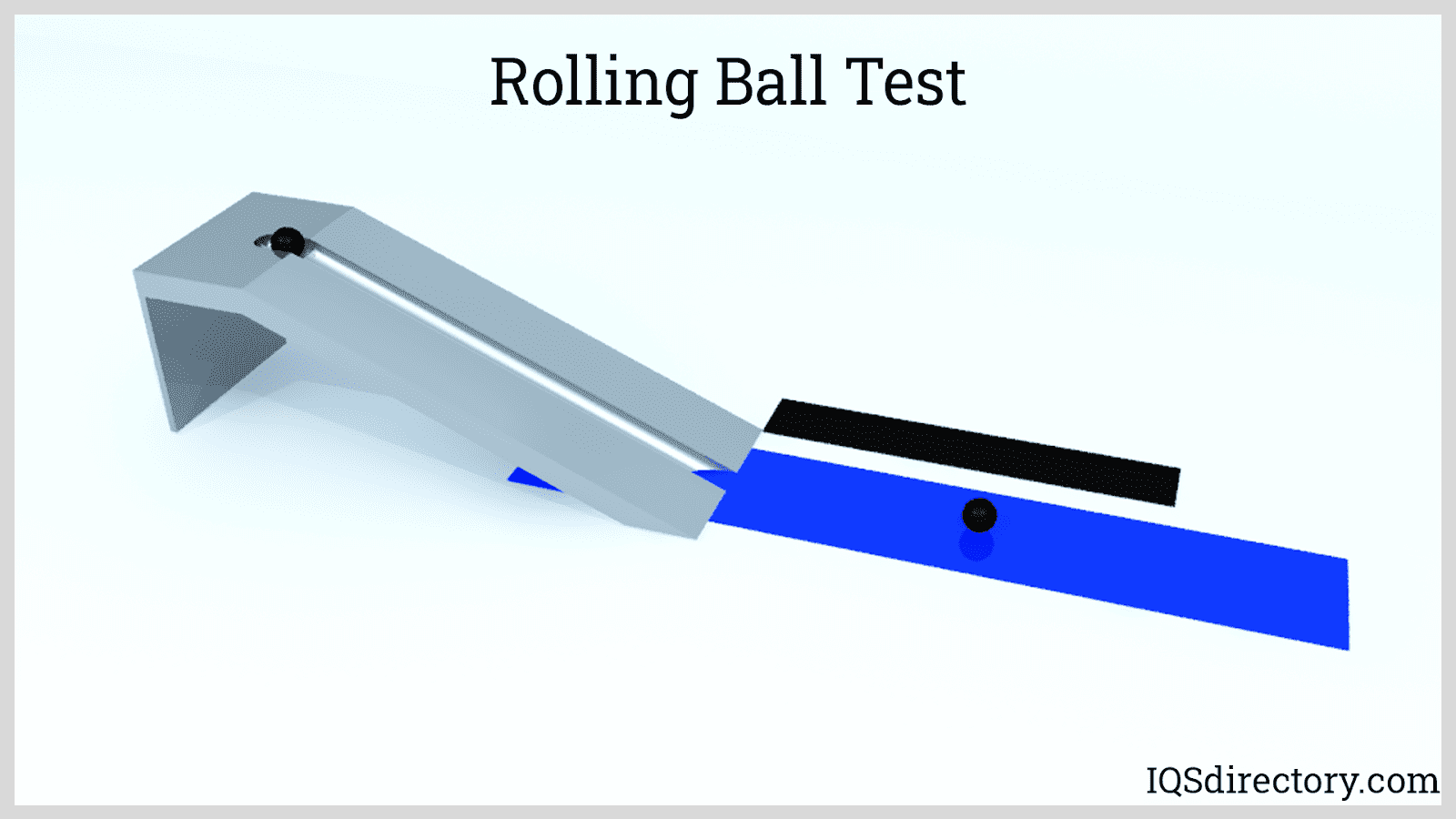

The Rolling Ball Test and Loop Tack Test are the most common quality control checks used to assess the tackiness of the adhesive tapes being produced.

- Rolling Ball Test: The rolling ball test directly gauges the adhesive behavior of the adhesive tape. A steel ball with a standard weight and diameter is made to roll from the top of an inclined track which consists of the sticky side of the tape. The tackiness is measured by the distance traveled by the ball on the sticky tape track; the shorter the distance, the greater the tack.

- Loop Tack Test: The loop tack test is a quantitative and repeatable method to assess adhesive tape tackiness. A loop of adhesive tape is attached to the probe of a tensile tester machine. The loop is made to contact with a horizontal surface for a short time, then the tool pulls it away. Numerical values of the bond’s tensile strength are recorded and subjected to evaluation.

Reference: https://www.iqsdirectory.com/articles/tape-suppliers/adhesive-tape.html?msID=1f7798fc-4305-49eb-8ba4-85ca244c575d#different-types-of-adhesive-tapes

Read MorePress Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More