Low Temperature Mounting Solution

At high latitudes or in cold regions, the temperature in winter is often very low.

Generally, the glue of the acrylic system has no way to resist the low temperature operating environment. However, and hot melt adhesive doesn't resist a hot environment. It's hard to find a universal material to try out all the environments.

If there is no low-temperature solution. This is easy to cause the phenomenon of falling off. Our special formulation will pass the laboratory low-temperature adhesion and shear test.

Moreover, we also have real cases complete the field test in Germany. Not just an indoor test, but an outdoor automotive test.

Consumers can fully believe that our experience, strength, and responsibility can be tested.

- Related Products

Laminating Film

Celadon Laminating Calendaring Vinyl Film is an ultra-clear, soft flexible 80μm PVC overlaminate film especially designed to protect large and medium size digital prints, special powerful glue for residue free design.Celadon Lminate film has an excellent conformability and reliable performance over time, these products are especially suited for partial or total wrapping of vehicles and corrugated surfaces.The product is compatible with the standard digital printing techniques of solvent, ecosolvent and latex.

Digital Printing Vinyl (SAV)

Celadon Opaque Self-adhesive Calendaring Vinyl Film is a premium quality calendar film designed for use in signage markets where high quality film finish and cost-effective full color wrapping is required. The Celadon Easy Apply feature allows for faster positioning, special powerful glue for residue free design.

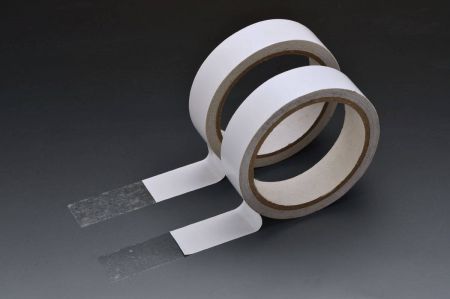

Tissue Double Coated Adhesive Tape

DS1-ABW49100

Description During the lifetime of vehicle, boat or yacht static and dynamic stresses act upon the constructive bond between the object and the subject part. Celadon® Double Coated Tape creates a powerful bond even between materials with different surface characteristics, such as low surface energy, EVA, EPDM form, plastic parts connection. Celadon Tissue Double Coated Adhesive Tape is 0.15mm double coated with solvent base poly-acrylic pressure sensitive adhesive and backing with 110gsm silicon coated release paper liner. Application Techniques The bond strength of Celadon depends on the area of adhesive to surface contact developed during application and substrate type and surface conditions. For maximum bond strength, the surfaces should be thoroughly cleaned with a 50:50 mixture of isopropyl alcohol and water. Ideal tape application is accomplished when the temperature is between 21°C-38°C (70°F-100°F) and the bond is allowed to dwell 72 hours. Initial tape application to surfaces at temperatures below 10°C (50°F) is not recommended. Moderate heat lamination (65°C at 72.5 psi for 1-5 minutes) is recommended on rough surfaces.STORAGE and SHELF LIFE The shelf life of Celadon Adhesive Transfer Tape ATR2165 is 6 months from the date of manufacture when stored in the original packaging materials and stored at 21°C (70°F) and 50% relative humidity.

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More