Intruction of Adhesive Tape - The Science of Adhesive Tapes

Parts of the Bond

The bonding layer made by an adhesive tape, shown macroscopically in the image below, presents a cross-section of a bond. The layer consists of an adhesion zone, cohesion zone, and a transition layer.

The adhesion zone is the interfacial layer between the adhesive and the substrate. The cohesion zone is the pure adhesive layer that holds the adhesive and the backing material, or another substrate if the adhesive is unsupported. The transition layer is intermediate between the adhesion and cohesion zones.

Mechanism of Action

The mechanism of adhesive tape bonding occurs as follows. These steps can be accomplished instantly after the activation of the pressure-sensitive adhesive.

- The pressure-sensitive adhesive on the tape is made to contact with the substrate by minimal pressure.

- Adhesive increases its surface area and penetrates through the surface of the substrate.

- Adhesive sets on the substrate, producing a strong bond.

The three elements of a pressure-sensitive adhesive tape to achieve a successful bond are adhesion, cohesion, and tackiness.

- Adhesion: Adhesion refers to the ability of an adhesive to stick on the surface of the substrate through adhesive forces. Adhesive forces refer to the attraction of two different materials. When the substrate and the adhesive molecules come in close proximity, adhesion forces occur at the microscopic level through intermolecular forces (e.g., van der Waals forces, dispersion forces) between them.

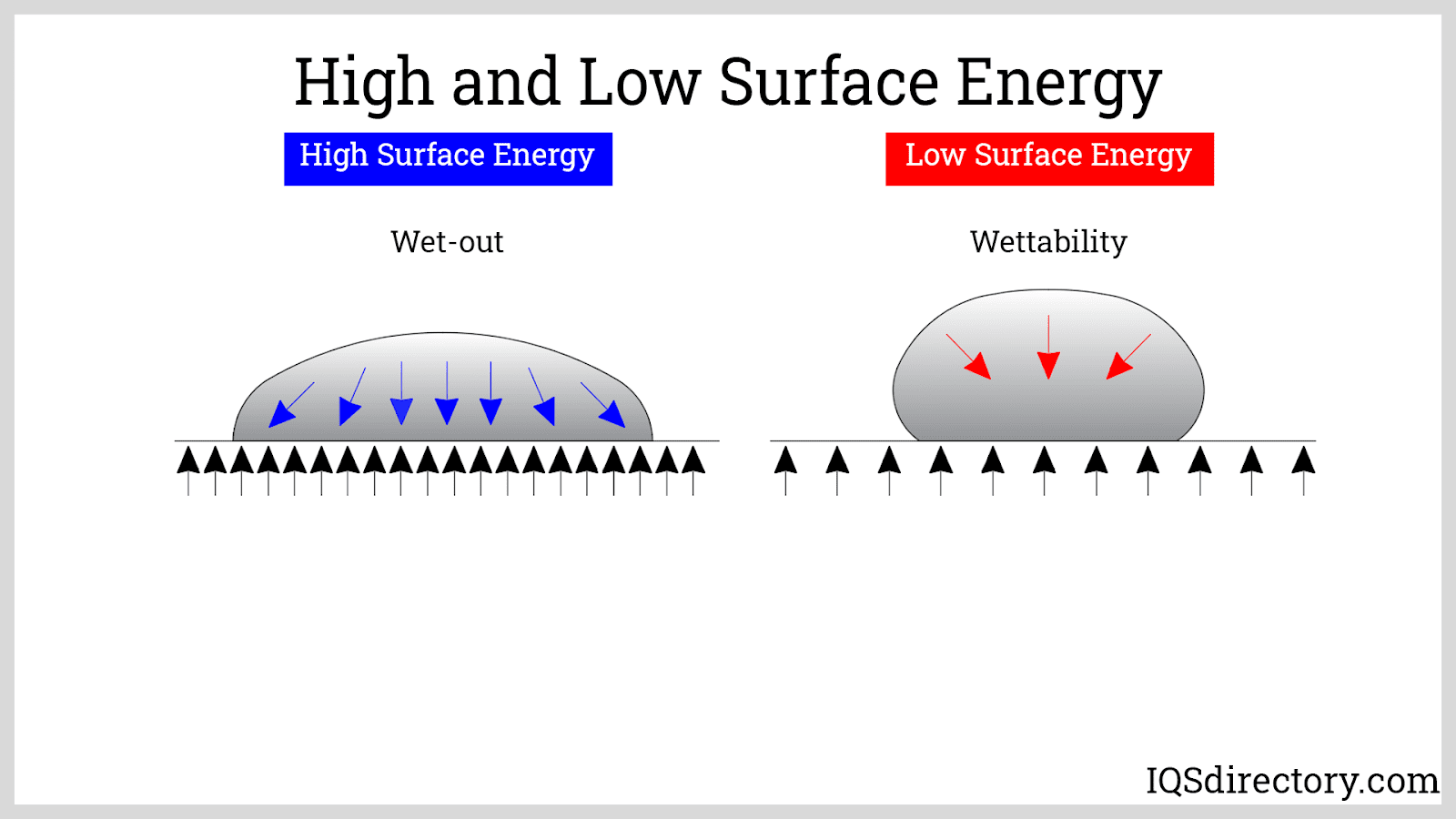

Surface energy is one of the properties which determines the wettability of the substrate when it comes in contact with the adhesive. Wettability is important to penetrate the surface of the substrate, thus making a continuous bond.

Surface energy is defined as the sum of the intermolecular forces, and the attraction and repulsion energies which a liquid exerts on the surface of a solid. If the substrate has high surface energy, the adhesive will easily flow on its surface and more surface area will be covered. Some of the high-energy substrates include polycarbonate, polyvinyl chloride, and zinc. On the other hand, if the substrate has low surface energy, the adhesive will build up as “small beads” and only a small area will be covered. Low surface energy substrates include Teflon, rubber, powder coatings, etc.

Surface contaminants prevent the fusion of the adhesive into the substrate. Therefore, it is important to keep the surface free from grease, dirt, and moisture before application of the adhesive tape.

- Cohesion: Cohesion is the inner strength of the adhesive. It refers to the bonding of the adhesive within itself. Cohesion holds the adhesive layer intact and prevents it from splitting.

Cohesive forces attract the neighboring molecules of a liquid by pulling it inward. Molecules at the surface of the liquid have greater attractive forces that bind them together. This phenomenon is responsible for the property of a liquid called surface tension. Surface tension is the ability of the adhesive to resist deformation on the surface of a solid, thus reducing its surface area. In the case of adhesive tapes, the molecules of the adhesive must be strong cohesive forces to hold and maintain the bond over time.

Silicone is an example of a liquid with high surface tension. If silicone is present as a coating on the surface of the substrate, it will be difficult to be wetted by the adhesive. If used as an adhesive, on the other hand, it will produce a durable bond.

Adhesion and cohesion must be considered when formulating or choosing the right adhesives. An ideal bond consists of a combination of a high surface energy substrate and a low surface tension adhesive. To achieve good wetting of the substrate, adhesive forces must be greater compared to cohesive forces and the contact angle must be less than 90°.

- Tackiness: Tackiness refers to the characteristic of a pressure-sensitive tape by which the adhesive sticks to the surface of the substrate under minimal pressure. All pressure-sensitive adhesives are activated by an initial finger pressure applied to the tape, usually from 14.5 to 29 psi. The required pressure and contact time for the adhesive tape to stick varies according to the type of adhesive and substrate material. Less pressure and contact time are required to stick for adhesive tapes with higher tack.

The phenomenon described is attributed to the viscoelasticity of the adhesive at room temperature. Viscoelastic objects are materials that possess both viscous and elastic characteristics. When gentle pressure is applied to the tape, it decreases its viscosity thus encouraging flow on the substrate at the microscopic level. Due to its elastic property, the original viscosity is regained with stronger intermolecular force with the substrate.

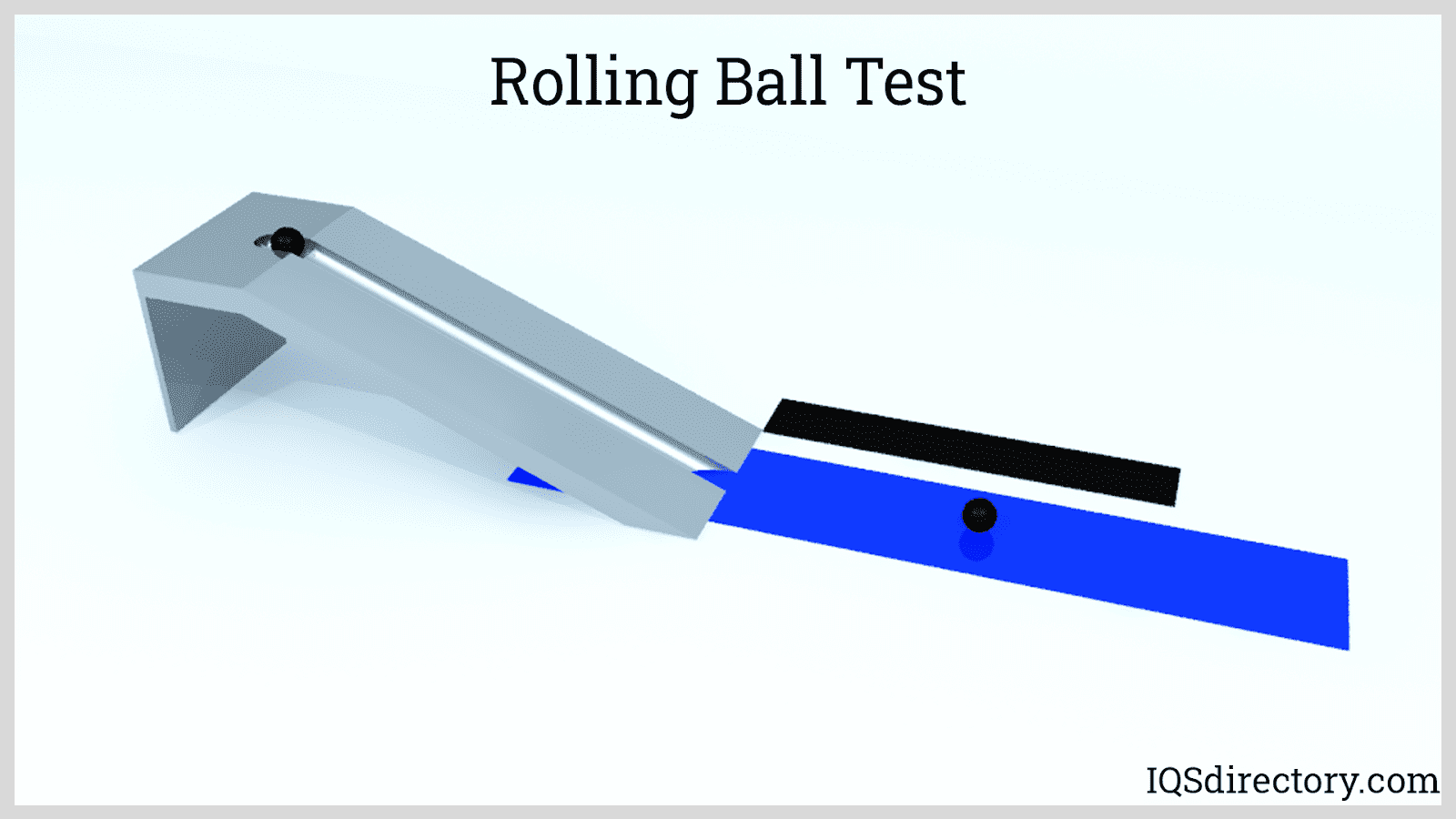

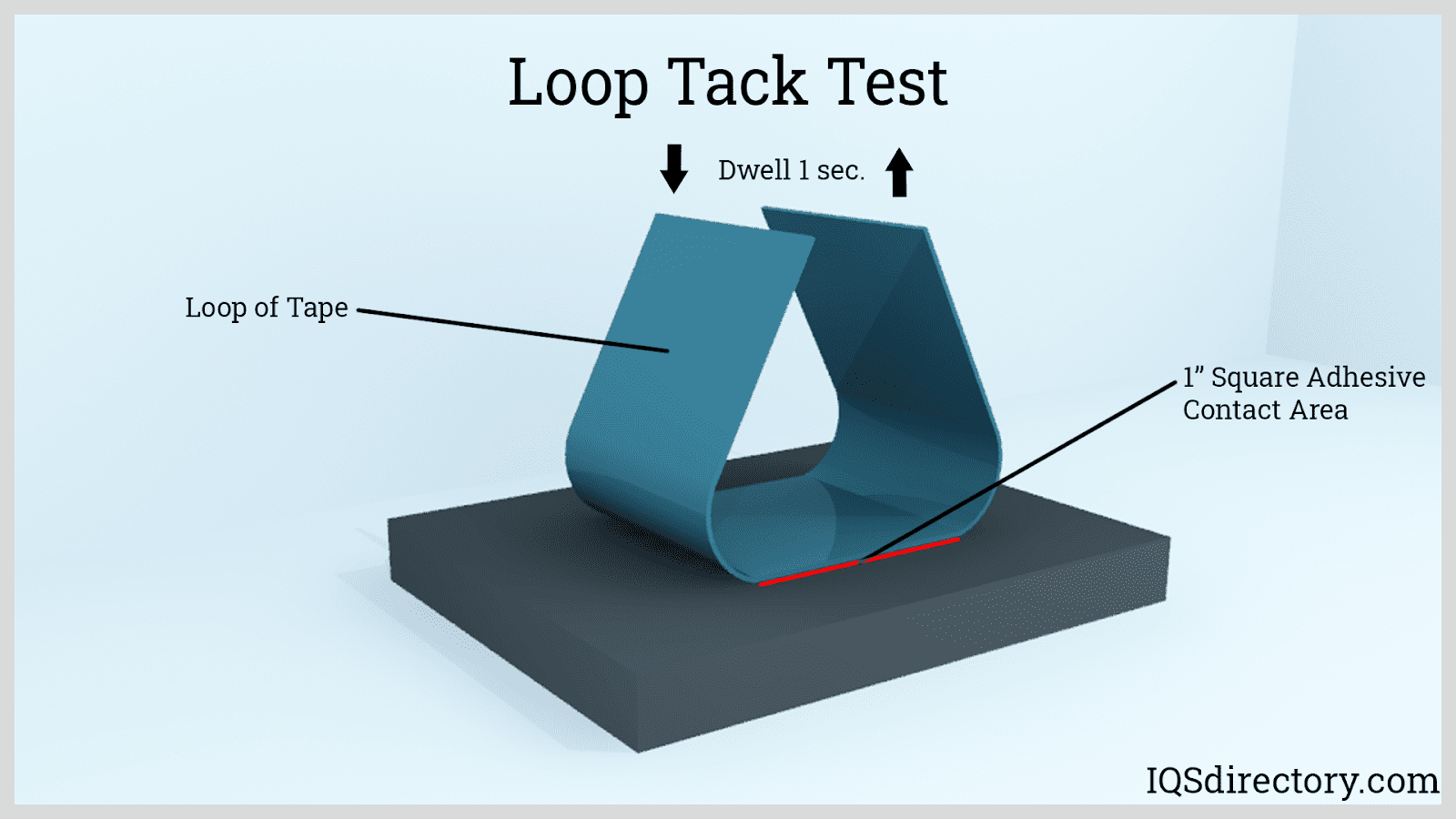

The Rolling Ball Test and Loop Tack Test are the most common quality control checks used to assess the tackiness of the adhesive tapes being produced.

- Rolling Ball Test: The rolling ball test directly gauges the adhesive behavior of the adhesive tape. A steel ball with a standard weight and diameter is made to roll from the top of an inclined track which consists of the sticky side of the tape. The tackiness is measured by the distance traveled by the ball on the sticky tape track; the shorter the distance, the greater the tack.

- Loop Tack Test: The loop tack test is a quantitative and repeatable method to assess adhesive tape tackiness. A loop of adhesive tape is attached to the probe of a tensile tester machine. The loop is made to contact with a horizontal surface for a short time, then the tool pulls it away. Numerical values of the bond’s tensile strength are recorded and subjected to evaluation.

Reference: https://www.iqsdirectory.com/articles/tape-suppliers/adhesive-tape.html?msID=1f7798fc-4305-49eb-8ba4-85ca244c575d#different-types-of-adhesive-tapes

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More